Filtration Systems

Filtration systems are advanced engineering solutions designed to purify and clarify process streams by separating unwanted elements and removing suspended debris. These systems serve as critical components in a wide range of industries where the removal of contaminants from air, water, gas, or process fluids is essential for operational efficiency, compliance, and product quality. Typically, a filtration system consists of specialized filtration media—such as membranes, screens, or cartridges—housed within robust frames or enclosures. Many industrial filters also incorporate additional chambers to store collected contaminants or to direct processed streams to subsequent treatment stages, ensuring seamless integration into complex workflows.

It is important to clarify terminology: the term “rejection filter” is not used to describe air or fluid filtration devices. Instead, a rejection filter refers to a specific type of filter in the field of signal processing, designed to block unwanted frequencies rather than physical particles or contaminants.

Filter Applications

The primary objective of a filtration system is to deliver air, water, or process fluids that meet stringent purity standards required for specific applications and industries. By reliably removing particulates, contaminants, and suspended solids, filtration systems contribute to improved process efficiency, equipment longevity, regulatory compliance, and end-product safety. In addition to clarifying the main process stream, advanced filtration solutions may also focus on secondary goals such as capturing filter cake for resource recovery, protecting downstream equipment, or preserving valuable clarified fluids for reuse.

Industrial filtration systems are indispensable in a wide array of sectors and processes. Some common applications include:

- Water and Wastewater Treatment: Removal of suspended solids, bacteria, and chemicals from municipal and industrial water supplies to produce potable water and comply with environmental regulations.

- Industrial Process Fluids: Filtration of coolants, corrosive chemicals, hydraulic fluids, lubricants, and other specialty fluids to minimize wear and extend equipment life.

- Petroleum and Energy: Purification of gasoline, diesel fuel, and oil to reduce engine fouling and optimize combustion efficiency.

- Food and Beverage Processing: Use of filtration in bottling lines, breweries, dairy production, and potable water systems (e.g., refrigerator water filters) to prevent contamination and ensure product quality.

- Pharmaceutical and Healthcare: Sterilization and removal of pyrogens, bacteria, and particulates in drug manufacturing, laboratory processes, and hospital HVAC systems.

- Automotive and Transportation: Air intake, exhaust filtration, and oil filtration to protect engines and improve air quality.

- HVAC and Cleanroom Environments: Filtration of air in heating, ventilation, and air conditioning systems, as well as in controlled environments such as semiconductor fabrication and pharmaceutical production.

- Agriculture and Irrigation: Filtering water for crop irrigation and livestock, preventing emitter clogging and improving system longevity.

- Mining, Pulp and Paper: Removal of abrasive solids and contaminants to protect machinery and ensure compliance with discharge regulations.

- Recreation and Pools: Pool filtration systems, including sand and cartridge filters, to maintain water clarity and safety.

If you’re searching for high-performance filtration systems for your facility or project, explore solutions that align with your industry’s requirements and regulatory standards. Our comprehensive product offerings serve the water and air filtration needs of sectors such as wastewater management, recreation, food and beverage, healthcare, agriculture, chemical processing, pharmaceuticals, automotive, and many more.

Filter History

The evolution of filtration systems traces back thousands of years, highlighting humanity’s ongoing pursuit of clean water, air, and process fluids. Ancient Egyptian hieroglyphs from around the 15th century BC depict early water purification methods using sand filtration, demonstrating the fundamental need for clean water in early civilizations.

Significant milestones in filtration history include:

- Hippocrates (460–370 BC): The Greek physician advocated boiling and filtering water through a cloth bag—known as the Hippocratic Sleeve—for enhanced purity and patient health.

- Arabian Alchemy (8th Century AD): Pioneers like Gerber developed primitive distillation and purification apparatuses to produce clean water.

- Scientific Discovery (17th Century): Sir Francis Bacon’s experiments with sand filtration and the subsequent advent of the microscope by Hooke and van Leeuwenhoek enabled the study of waterborne pathogens, paving the way for modern filtration technology.

- Industrial Era (1804–1839): John Gibb’s development of sand filtration and the opening of the Chelsea Waterworks in London marked the birth of municipal water treatment plants.

- Public Health Breakthrough (1854): Dr. John Snow’s identification of cholera’s link to contaminated water in London prompted sweeping reforms in water filtration and public sanitation, influencing global standards for potable water safety.

- Regulatory Advances (20th Century): The United States implemented its first drinking water standards in 1914, with nationwide enforcement established in the 1940s. The Clean Water Act of 1972 required industrial manufacturers to limit pollutants discharged into public water supplies, accelerating the adoption of advanced filtration systems across all sectors.

- Membrane Filtration (Mid-20th Century): Innovations at UCLA and the University of Florida led to the development of high flux membranes and reverse osmosis (RO) technology, revolutionizing desalination and high-purity water production. Cape Coral, Florida, pioneered municipal RO systems by 1977, eventually processing millions of gallons of potable water daily.

Today, filtration technology continues to advance, addressing new challenges such as air pollution, microplastics, and emerging contaminants. High-efficiency filters now play a pivotal role in environmental stewardship, public health protection, and sustainable manufacturing. Whether used in household water pitchers or industrial-scale pharmaceutical manufacturing, filtration systems are integral to modern society’s well-being.

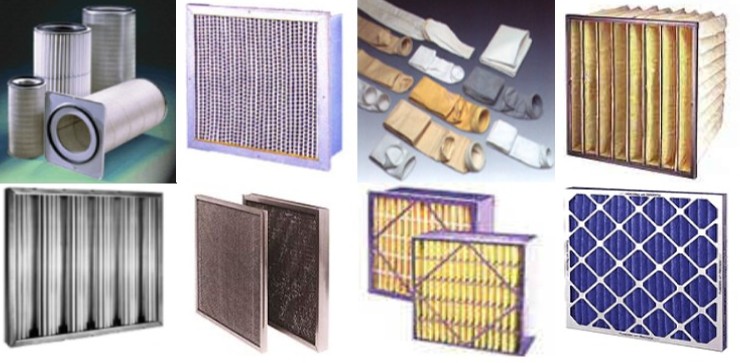

Types of Filters

Modern filtration systems are available in an extensive range of types, each engineered for specific contaminants, flow rates, pressure conditions, and industry applications. Understanding the distinctions between filter types is crucial for selecting the best solution for your needs. Here is an in-depth overview of the most common filtration system varieties and their typical uses:

- Vacuum Filters: These filters generate a vacuum on the outlet side, drawing process streams through filtration screens. Commonly used for dewatering, slurry thickening, and solid/liquid separation in mining and chemical processing, vacuum filters offer high throughput and reliable cake recovery.

- Pressure Filters: Utilizing pressurized or compressed air, pressure filters force fluids through their media for rapid removal of suspended debris. They are widely used in water treatment, beverage processing, and petrochemical refining for their ability to handle high contaminant loads and variable flow rates.

- Membrane Filtration: Employing semi-permeable films, membrane systems (including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis) selectively allow water or gas molecules to pass while blocking larger particles, bacteria, and dissolved solids. Common applications include desalination, sterile filtration in pharmaceuticals, and blood purification (dialysis).

- Industrial Filters: These are robust, high-capacity units designed to remove particulates, oils, and contaminants from process air, fluids, and gases in manufacturing, petrochemical, and automotive environments.

- Surface Filters: Utilizing screens, meshes, or pleated cartridges, surface filters capture particles on the filter’s external surface. Ideal for pre-filtration, bag filters, and cartridge filters in water treatment and HVAC systems.

- Oil Filters: Essential for removing contaminants from hydraulic, engine, and lubrication oils. Oil filtration extends equipment life, maintains fluid cleanliness, and reduces maintenance costs in automotive, agricultural, and heavy machinery applications.

- Gravity and Centrifugal Filters: Relying on hydrostatic pressure or centrifugal force, these filters separate heavier particulates from liquids or gases, commonly used in bulk solids recovery and wastewater treatment.

- Coalescing Filters: Specialized for capturing fine mists, oil droplets, and vapors from air or gas streams in compressed air systems, natural gas pipelines, and cleanrooms. Coalescing filters are critical for maintaining dry, contaminant-free air in sensitive applications.

- Chemical Filters: Employ chemical media (such as activated carbon or ion exchange resins) to adsorb, react with, or neutralize specific contaminants. Popular in gas purification, odor control, and water softening systems.

- Biological Filters: Use naturally occurring or engineered microbes to break down organic contaminants in water or wastewater. Diatomaceous earth filters are a classic example, and biological filtration is increasingly important in aquaculture and environmental remediation.

- Ceramic Filters: Composed of porous ceramic material, these filters physically trap fine particles and bacteria. Widely used in potable water filtration, laboratory settings, and gravity-fed filtration systems.

- Electrodialysis (ED) and Electrodialysis Reversal (EDR): Utilize ion-selective membranes and electrical currents to remove ionic contaminants from water. EDR systems periodically reverse current direction to minimize fouling, making them suitable for desalination and industrial water recycling.

- Reverse Osmosis (RO), Electrodeionization (EDI), and Ultrafiltration (UF): Advanced filtration technologies for removing dissolved solids, ions, and ultra-fine particulates. RO is preferred in seawater desalination, while EDI combines ion exchange and electricity for ultra-pure water in electronics and pharmaceuticals. UF is ideal for virus and protein removal.

- HEPA Filters: High Efficiency Particulate Air (HEPA) filters capture and remove 99.97% (or more) of airborne particles ≥0.3 microns. They are essential in hospitals, laboratories, cleanrooms, aircraft cabins, and vacuum cleaners, offering unmatched protection against dust, pollen, mold, and pathogens.

- ULPA Filters: Ultra Low Penetration Air (ULPA) filters provide even higher efficiency than HEPA, removing 99.999% of particles as small as 0.1 microns. ULPA filters are used in semiconductor manufacturing, pharmaceutical production, and other critical environments where particle control is paramount.

- HVAC Filters: Designed for heating, ventilation, and air conditioning systems, these filters improve indoor air quality by capturing dust, allergens, and microorganisms. MERV-rated filters help facilities meet health and safety standards.

- Variable Filters: Combine multiple filtration products and technologies within a single system for comprehensive contaminant removal and process flexibility. These hybrid systems are tailored for demanding industrial and municipal applications.

- Progressive Filtration Systems: Feature sequential layers of filter media with increasing restrictiveness, allowing for staged particle removal. This design enhances filtration efficiency, extends filter life, and reduces maintenance in applications where solids recovery is critical.

- Water Filters: Remove particulate, chemical, and biological contaminants from liquids or gases, improving taste, odor, safety, and compliance. Water filters are essential for drinking water treatment, industrial process water, and recreational uses.

Need help choosing the right filter for your application? Ask: What contaminants do I need to remove? What flow rate and capacity are required? Are there regulatory standards I must meet?

Filtered water is crucial for health, taste, and safety. Water filtration systems protect against waterborne diseases and health risks by removing sediment, pathogens, chemicals, and other harmful substances. Effective filtration is especially vital for vulnerable populations such as children, the elderly, and those with compromised immune systems.

The Types of Water Filtration Process

The water filtration process encompasses a variety of methods, each suited to specific contaminants and use cases. Understanding these processes helps buyers and facility managers select the optimal filtration solution for their needs. Common water filtration techniques include:

- Absorption: Carbon filters, especially those using activated carbon, excel at absorbing impurities. Their porous structure captures chemical contaminants, such as chlorine, pesticides, volatile organic compounds (VOCs), and other undesirable substances, making them popular in home water filters and industrial purification systems.

- Mechanical Filtration: This method physically removes particles using a barrier, such as mesh screens or ceramic elements. Mechanical filters are available in a range of pore sizes, capable of capturing everything from visible debris to microbiological contaminants, and are widely used as pre-filters in water treatment plants and residential systems.

- UV Radiation: Ultraviolet light exposure effectively inactivates bacteria, viruses, and protozoa, preventing their reproduction. UV systems are often combined with other filtration methods, such as RO, to ensure removal of heavy metals and chemical pollutants not affected by UV alone.

- Sequestration: This chemical process uses food-grade polyphosphate to bind minerals such as calcium and magnesium, inhibiting scale buildup in plumbing and appliances. Sequestration keeps minerals suspended, preventing limescale without actually softening the water.

- Ion Exchange: By exchanging magnesium and calcium ions for sodium or hydrogen ions, ion exchange systems soften water, reducing limescale and improving suitability for high-temperature and industrial applications.

- Reverse Osmosis (RO): RO technology forces water through a semi-permeable membrane under pressure, removing dissolved inorganic solids, heavy metals, and other contaminants. RO systems are widely used in residential, commercial, and municipal water treatment for their exceptional purity levels.

- Distillation: Water is boiled, and the resulting steam is condensed to separate pure water from impurities and minerals. While highly effective, distillation is slower and less energy-efficient than other advanced filtration methods.

- Water Rotameter: Essential for monitoring water flow rates, rotameters consist of a tube and float. As flow increases, the float rises, providing a visual and linear indication of volumetric flow. Accurate flow measurement is critical for dosing chemicals, process control, and compliance in water treatment facilities.

Wondering which water filtration process is right for your application? Consider: What types of contaminants are present in your source water? Are you treating municipal, well, or industrial water? What is your required flow rate and system footprint?

Filter Design and Customization

Engineering an effective filtration system requires careful consideration of several critical design factors:

- Filtration Rate: The speed at which fluids or air pass through the filter, directly impacting particulate removal efficiency and process throughput.

- Filter Location: Filters can be installed at intake, inline, or exhaust points. Many systems utilize filtration at multiple stages to maximize contaminant removal and equipment protection.

- Stream Viscosity and Temperature: The properties of the process fluid dictate the choice of filter media and housing materials to ensure chemical compatibility and mechanical integrity.

- Load Capacity and Maximum Flow: High-capacity filters are engineered to handle large volumes and high contaminant loads without frequent maintenance or performance loss.

- Absorption and Pressure Drop: Balanced design minimizes pressure drop while maximizing contaminant uptake, optimizing energy efficiency and filter lifespan.

- Continuous vs. Batch Operation: Filters can be designed for continuous flow or batch processing, depending on production needs and contaminant load profiles.

Before finalizing a system design, manufacturers analyze expected particulate sizes, slurry characteristics, and compatibility between filter materials and process streams. Custom filtration solutions may be required for challenging applications, including aggressive chemicals, high temperatures, or unique process requirements.

Materials and Methods

Filtration system manufacturers employ a diverse array of materials to construct filter housings and media, including:

- Metals: Aluminum, steel, stainless steel for durability and corrosion resistance.

- Polymers: Plastics such as Teflon and nylon for chemical compatibility and lightweight construction.

- Carbon: Activated carbon and other forms for chemical adsorption.

- Natural and Synthetic Fibers: Used in depth and surface filters for particulate capture.

- Resins, Sand, and Diatomaceous Earth: For specialized filtration and biological treatment.

Separation methods include membrane filtration, gravity settling, centrifugal force, chemical precipitation, biological digestion, and electrostatic attraction. Advanced systems may integrate multiple methods for comprehensive contaminant removal.

Looking for a custom filtration solution? Ask: What are your process conditions (temperature, pressure, chemical exposure)? What contaminants must be removed? Is modular scalability important for future expansion?

Filter Safety and Compliance Standards

Compliance with safety and environmental standards is paramount when selecting and operating filtration systems. Key regulatory organizations include:

- ISO (International Organization for Standardization): Technical Committee 131 oversees filtration standards applicable to various industries worldwide.

- OSHA (Occupational Safety and Health Administration): Establishes workplace safety guidelines for filtration equipment installation and operation.

- EPA (Environmental Protection Agency): Regulates emissions, effluent quality, and environmental impact of filtration systems.

- ASTM, SAE, ANSI: Develop test methods, performance benchmarks, and material specifications for filter products.

Adhering to these standards ensures safe operation, environmental protection, and product reliability. For industry-specific guidance, consult with regulatory experts or filtration system suppliers with proven compliance expertise.

Things to Consider Regarding Filter Manufacturers

Choosing the right filtration system manufacturer is essential for achieving optimal performance, reliability, and return on investment. Here’s a step-by-step approach for buyers and facility managers:

- Research reputable filtration system manufacturers with a track record in your industry and application domain.

- Evaluate product offerings, customization capabilities, and technical support. Narrow your selection to three or four top suppliers.

- Contact each manufacturer to discuss your application in detail. Share specifics regarding contaminant profiles, flow rates, budget, project timelines, regulatory requirements, and delivery preferences.

- Compare proposals, paying close attention to filter media quality, system integration, maintenance requirements, warranty, and after-sales support.

- Select the partner that aligns best with your operational goals and provides demonstrated expertise in your industry.

Ready to take the next step? Explore: What filtration technologies are best for your process? How do maintenance cycles and total cost of ownership compare?

More Filter Manufacturers

What is a filtration system and why is it important?

A filtration system is an engineered solution designed to purify and clarify process streams by removing unwanted elements and suspended debris. It is essential across many industries to ensure operational efficiency, compliance, equipment protection, and high product quality by removing contaminants from air, water, gas, or process fluids.

What are the main types of filters used in industry?

Common types of industrial filters include vacuum filters, pressure filters, membrane filters (such as reverse osmosis and ultrafiltration), surface filters, oil filters, gravity and centrifugal filters, coalescing filters, chemical filters, biological filters, ceramic filters, electrodialysis systems, HEPA and ULPA filters, HVAC filters, variable filters, progressive filtration systems, and water filters. Each is designed for specific contaminants, capacities, and industry needs.

How does water filtration work and what methods are used?

Water filtration can involve various methods such as absorption (using activated carbon), mechanical filtration (using mesh or ceramic elements), UV radiation (to inactivate microorganisms), sequestration (binding minerals to prevent scale), ion exchange (replacing hardness ions), reverse osmosis (forcing water through a semi-permeable membrane), and distillation. The method selected depends on the contaminants present and the desired water quality.

What factors should be considered when designing a filtration system?

Designing a filtration system requires considering filtration rate, filter location, process stream viscosity and temperature, load capacity, pressure drop, and whether the operation will be continuous or batch. Custom solutions may be necessary for challenging conditions involving specific contaminants, high temperatures, or unique process requirements.

What are key safety and compliance standards for filtration systems?

Important standards are established by organizations such as ISO (Technical Committee 131), OSHA, the EPA, ASTM, SAE, and ANSI. These bodies regulate various aspects of filtration systems from workplace safety and environmental emissions to material specifications and testing protocols, ensuring systems operate safely and effectively.

How should I choose the right filtration system manufacturer?

Select manufacturers with proven expertise and a successful track record in your industry. Evaluate their product offerings, customization, and technical support. Communicate your application needs, compare proposals for quality, integration, maintenance, and support, and choose a partner that aligns best with your operational and regulatory requirements.

What materials are commonly used to construct filtration systems?

Filtration systems are made from materials such as metals (aluminum, steel, stainless steel), polymers (Teflon, nylon), activated carbon, natural and synthetic fibers, resins, sand, and diatomaceous earth. The choice of material depends on the application’s chemical compatibility, strength, and filtration requirements.

Air Filters

Air Filters Liquid Filters

Liquid Filters Filtering Systems

Filtering Systems Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services